- Home

- Products

- Laser Cutting Machine

- General Non-metal Laser Cutting Machine, CMA1309-B-A

General Non-metal Laser Cutting Machine

CMA1309-B-A1. Fully enclosed protective cover structure.

2. The beam structure is made of high strength aluminum alloy, compared with the traditional steel beam, this general non-metal laser cutting machine has the advantages of light weight, small resonance, and smoother operation.

3. High dynamic stepper motor and high precision linear guide rail are adopted to ensure high dynamic response performance and high load capacity.

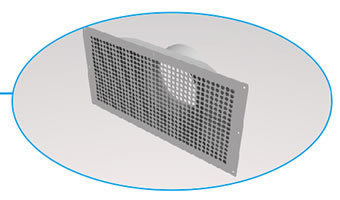

4. Box type ventilation device is used for cleaning work environment.

5. Supports cutting density board, acrylic and other materials.

| Model | CMA1309-B-A |

| Laser tube | 80W (60W, 100W, 130W optional) |

| Continuous cutting function | Yes |

| Working speed | 0~30m/min |

| Repeated positioning accuracy | ≤±0.05mm |

| Drawing format | AI, DXF, BMP, JPGE, PLT, DST, DSB, etc. |

| Power supply | AC220-240V, 50/60Hz |

| Transmission system | Guide rail and belt |

| Positioning system | Red light pointer |

| Base plate | Interlocking base plate |

| Cooling method | Water cooling |

| Fan | 750W |

| Laser control system | SmartCarve4.3 |

| Machine power | ≤3.2KW (with auxiliary machine) |

| Total weight | 480kg |

| Packing dimensions | 1760×1960×1200mm |

Applicable Materials

Nonmetal: wood, acrylic, MDF,plastic, paper, etc.

Machine Parts

Development goal of CMA series laser machine is to significantly improve the stability with high speed, and laser processing efficiency. The overall weight of this laser cutter has increased 20% than the same type of the equipment. Its software design, mechanical structure design, ergonomic design and various device selection are strictly implementing the latest international standards. The cost of a single device is increased by 10% compared with the same type of the equipment. Stability, accuracy and speed can reach the world class laser equipment design standards.

-

Power supply of each auxiliary machine is designed and controlled together. The industrial site is fully in line with the requirements of 6S management.

-

The end cap in both sides adopts open design, the daily operation and maintenance of the non-metal laser cutting machie are greatly facilitated.

-

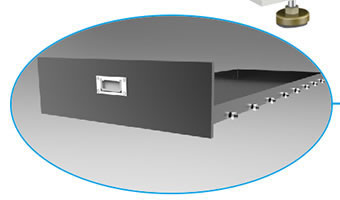

Main machine and base adopt T type bolt to achieve rapid assembly, which can provide a great convenience for temporary disassembly and assembly of laser cutter.

-

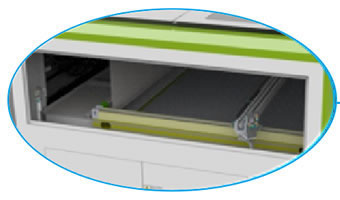

High quality encapsulated bearings are installated on both sides of the waste collection box.

-

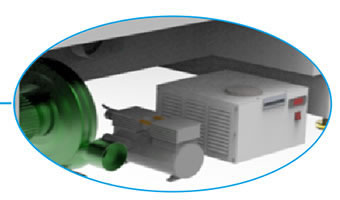

The auxiliary machinery storing design saves the floor area of metal laser cutting machine.

-

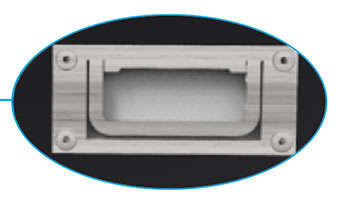

All handles and door locks use ergonomic design, which are extremely convenient.

-

Ventilation outlet is designed vertically, which can completely avoid the waste pumping into the ventilation system, and improve the smoke and dust removing effect instantly.

-

Hinge of front and rear end cap adopts built-in design, that makes whole machine body sealing more close and beautiful.

English

English India

India Canada

Canada Español

Español Français

Français Русский

Русский Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ประเทศไทย

ประเทศไทย Indonesia

Indonesia