- Home

- Products

- Laser Cutting Machine

- Light Guide Plate Processing Cutter and Engraver

Light Guide Plate Processing Cutter and Engraver

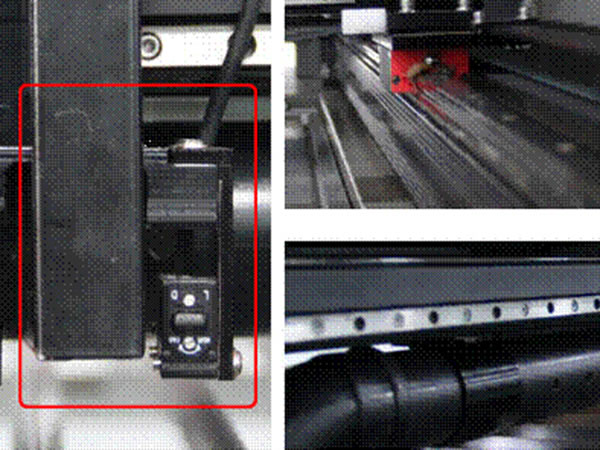

- Overall appearance of CMA1390LG

- Automatic focusing, linear guide rail, upper air vacuuming channel

- 80W CO2 laser tube

Software Features

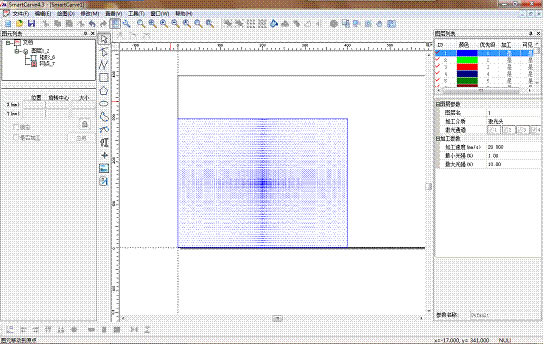

1) The software is specially designed for light guide plate industry. The dots of the light guide plate can be generated automatically by the software.

2) The size and pitch of dots can be changed gradually and automatically.

3) It supports variety of processing method including dot, bitmap, and lineation.

4) The software is compatible with the main designing software and it can automatically optimize the parameter.

5) It is able to design the light guide plate with multiple sides and various methods to guide light.

6) It supports the arrangement of irregular light guide plate.

Machine Features

1) The light guide plate processing cutter and engraver adopt automatic exhaust system to optimize the working environment.

2) It is capable of auto focusing and auto adjusting on focus size.

3) The flatness of the worktable is adjustable.

4) This machine is integrated with multiple functions including dot-making, lineation, cutting and engraving.

Constructions

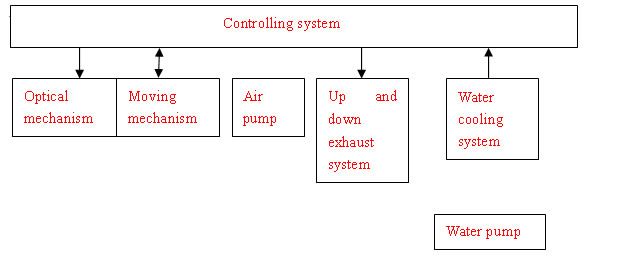

Controlling system

Moving mechanism

Optical mechanism

Vision mechanism

Air pump

Water pump

Up and down exhaust system

Technical parameters

Laser power: ≥30W

Length of laser wave: 10.6μm

Gross power: <1.5KW

Processing area: 1100mm×900mm

Max speed: 1000mm/s

Spot diameter: 0.2mm

Location precision: 0.05mm

Supply voltage: 220V AC 50Hz

Dimension: 1900mm×1390mm×1170mm

| Main features | Configuration 1 | Configuration 2 | Configuration 3 |

| Laser type | C40-L Coherent RF | CR-50Z China RF | 80W glass tube |

| Laser wavelength | 10640nm | 10640nm | 10640nm |

| Sweeping speed of light guide plate | 0-500mm/s | 0-400mm/s | 0-200mm/s |

| Cutting speed for 3mm Acrylic | 0-9mm/s | 0-12mm/s | 0-20mm/s |

| Thinnest focus light spot | 0.1mm | 0.1mm | 0.2mm |

| Repeat positioning precision | ±0.05mm | ±0.05mm | ±0.05mm |

| General power | < 2.5KW | < 2.5KW | < 1.0KW |

| Working area | 1100×900mm | 1100×900mm | 1100×900mm |

| Power supply | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Dimensions of the body | 1900×1560×1110mm | 1900×1560×1110mm | 1900×1560×1110mm |

| Weight of the machine | 350KG | 350KG | 350KG |

| Temperature | 0℃-45℃ (non condensing) | 0℃-45℃(non condensing) | 0℃-45℃(non condensing) |

| Humidity | 5%-95% | 5%-95% | 5%-95% |

| cooling | Water cooling | Water cooling | Water cooling |

| Light source | 40W America Coherent RF Generator | 50W domestic RF Generator | 80W glass tube |

| Laser frequency | 0~25KHz | 0~20KHz | |

| Laser beam mode | TEM00 | TEM00 | |

| Laser power stability | ±5% | ±5% | ±7% |

| Max dot speed | 500mm/s | 400mm/s | 250mm/s |

| Degree of orientation | Very good | Good | medium |

| Smallest focusing diameter | 0.08mm | 0.1mm | 0.2mm |

| Max cutting speed | Medium | Fast | Fast |

| Cooling method | Water cooling (match with 1600W chiller), Temp. accuracy controlled to ±0.1 ℃ | Water cooling (match with 1600W chiller), temp. accuracy controlled to ±0.1 ℃ | Water cooling (match with 1000W chiller), temp. accuracy controlled to ±0.1 ℃ |

| Lifetime | 25000 hours | 20000 hours | 5000hours |

| Efficiency of processing | Best, the minimum pitch can be adjusted to 0.2mm | Good ,the minimum pitch can be adjusted to 0.25mm | Not so good, the minimum pitch can be adjusted to 0.4mm |

| Maintenance | Modularity design, simple installation, light intensity is stable | Simple installation, free of maintenance, light intensity is stable | Installation need professional technology, light intensity is not so stable. |

| Cost | Highest | High | Low |

| Warranty for generator | 1year | 1year | 6month |

| Gas charging for generator | Yes | Yes | No |

| Mainframe | Item | Configuration | Spec. | Qty. | Remarks |

| Laser tube | ● | C-40L | 1 | 40W water cooling RF generator | |

| ○ | CR-50Z | 50W water cooling RF generator | |||

| ○ | 80W | CO2 laser tube | |||

| Laser power | ● | HF1000W-s-48 | 1 | Match with 40W imported generator | |

| ○ | HXT-3050A | Match with 50W generator | |||

| ○ | YMPS80B | Match with 80W RC | |||

| Beam Expander | ● | 2.5 times | 1 | Material: zinc | |

| Reflector | ● | 25mm×3mm | 3 | Material: golden silicon | |

| Focus | ● | 25.4mm, f=50.8mm | 1 | |

|

| X direction motor | ● | step forward | 1 | |

|

| Y direction motor | ● | step forward | 1 | |

|

| Z direction motor | ● | step forward | 1 | Focus can be adjusted automatically | |

| Transmission guide rail | ● | High speed linear guide rail | 4 | |

|

| Transmission belt | ● | Steel wire synchronous belt | 3 | |

|

| Security switch | ● | |

1 | |

|

| Workingtable | ● | Adjustable Stripped baseboard(special for light guide plate) | 1 | |

|

| Control mainboard | ● | 1.3# motherboard | 1 | |

|

| Operating software | ● | SmartCarve4.3 | 1 | WD6 softdog | |

| Accessories | Air pump | ● | 220V/50Hz/135W | 1 | Model: AC0-009D |

| Chiller | ● | SL-1 | 1 | Match with RF generator | |

| Water tank+ water pump | ○ | 544×425×295 (Water tank) + AP5500 (water pump) | Match with laser tube | ||

| Wind pump | ● | 550W | 1 | Up exhauster | |

| Wind pump | ● | 750W | 1 | Down exhauster | |

| ●Standard configuration ○Optional △Can be added ▲Can be used together with other items X no such configuration | |||||

Operating environment

1) Air humidity: 40%-80%, non-condensing

2) Environment temperature: 15-30℃

3) Power supply voltage: AC220V, 50Hz

4) Voltage Fluctuation: ±5%, International standard power net is suitable. If voltage fluctuation exceeds 5%, we need to add voltage stabilizing circuit for the machine.

5) The working environment for the equipment needs to be smoke-free without metal dust.

6) Cooling water must be the purified and deionized water. Distilled water is the best.

7) The running water or mineral water with mineral can't be used.

Application Material

Acrylic

Application Industry

Light guide plate

English

English India

India Canada

Canada Español

Español Français

Français Русский

Русский Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ประเทศไทย

ประเทศไทย Indonesia

Indonesia