- Home

- Products

- Laser Cutting Machine

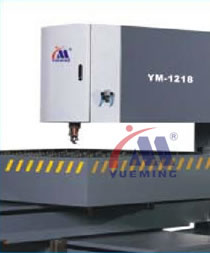

- Constant Optical Path Laser Cutting Machine, YM-1218

Constant Optical Path Laser Cutting Machine

YM-1218Features of Optical Path Laser Cutting Machine

1. YM-1218 CNC laser cutting machine is designed on the principle of constant light. Its laser power would not be affected by the distance of optical path, which ensures evenness and consistency of the cutting. It is also convenient for focusing and mainte nance. It has XY axis sliding bearing.

2. The laser cutting machine configures high quality axial flow CO2 laser generator. The laser beam from laser generator focuses on the cutting head after the transmission and treatment of optical path system. Then laser cutting is achieved with jetting gas by CNC system. The auxiliary machines include precision warm water cooling machine, oil free air compressor, cooling and filtering units of gas supply, dust suction device, three phase high power automated voltage regulator, etc.

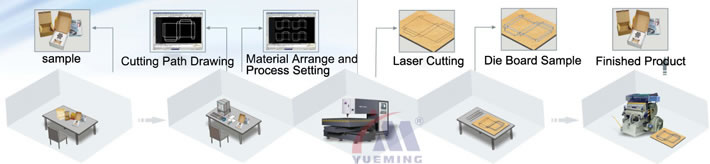

3. The control software of this laser machine can achieve auto programming, optimal layout of CAD/CAM on windows operating system, and can identifies DWG and DXF. Users can also establish their own laser cutting process database, and select the proper processing program from it directly in case of need.

4. Kay parts of the cutting machine is originally imported fro abroad or processed by introducing advanced technology, ensuring stable technical performance. The main parts include the hardwares of CNC system, precision ball bearing screw rods, drive system of liner guide, digital AC servo drives, laser generator resonant cavity, optical lens.

5. Shown here are Roots vacuum pump and rotary-vane vacuum pump as well as vacuum air system and pneumatic units.

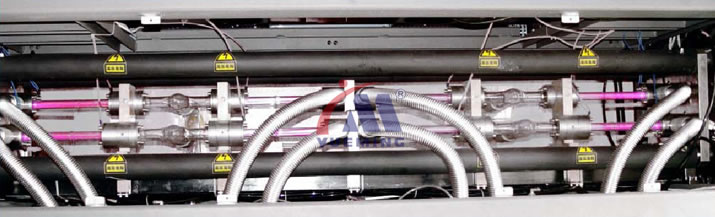

6. High power fast axis flow CO2 laser generator is made by introducing advanced technology.

1. YM-1218 digital control laser cutting machine is designed on the principle of constant light. Its power would not be affected by the optical path, which ensures even and consistent cutting. It is convenient for focusing and maintaining with an integral welding body which is rigid, stable and shatter-proof. It has cross sliding bearing.

2. It has precision ball screw rod and linear guide rail. The accurate and fast machine can operate at maximum 10m/min with a positioning deviation within ±0.05mm/m and a repeated positioning deviation of ±0.03mm.

3. The Germany power automation PA8000NT CNC system is powerful and is laser power adjustable. Z axis can adjust its distance with workpiece automatically. It features the functions such as fitting, reverence clearance compensation, screw pitch error compensation, cutting compensation.

4.The X,Y,Z axes are driven by Panasonic AC servo motor, which boasts good dynamic performance, quick respond, and free of maintenance.

5. It is configured with CAD/CAM automatic program and lay-outs optimization system as well as USB interfaces.

6. Ventilating system can protect the machine from smoking.

7. Our stable high power CO2 laser generator of fast axial flow is high performance and detachable from the cutting lathe. Longer service life of lens and better cutting results can be realized with the sealed reflector path.

-

Height sensor focus automatically and modular lens are easy to change.

-

We apply servo motors of famous brands such as Siemens and Mitsubishi.

-

High precision seamless ball screw rod.

High Power Fast Axis Flow CO2 Laser

1. The laser resonant cavity of invar steel structure is designed with multiply high vacuum degree technology and performs well.

2. The complete set of Japanese “SMC” Pneumatic components performs well with the stable, fast and reliable axial gas flow system.

3. It features oscillation containing of the longitudinal mode and transverse mode laser output. It boasts 450 linear polarization. Our lens applies the well known USA "II-VI" brand which has stable and quality output.

4 The module that is designed of reasonable structure is convenient for maintenance and is shatter-proof as well as dust proof.

Control System and Software

1. The high stable PLC system controls the USB port, fast analog input and output, fast digital value input and output modular.

2. Control software such as Windows operating system, PA 8000NT CNC system specially designed for laser lathe from the Power Automation, Laser power control, Z axis automatic tracking system. We achieve linear interpolation, circular interpolation, fitting, reverence clearance compensation, screw pitch error compensation and so forth with the above mentioned software.

3. The programming software specialized for laser processing is base don the Cad platform, realizing human machine interaction and making it easier for users to modify processing details such as path sequence, cutting direction , etc.

4. The Cutting Experts processing parameters works as a reference for automatic or manual cutting. In addition, users can built their own laser cutting data base according to their specific needs.

| CNC lathe parameter | Axial flow laser parameters | Others | ||||||

| Mode | Dimensions (mm) | Positioning precision | Repeated positioning accuracy | Max. speed | Mode | Rated power | Weight | Floor area |

| YM-1212 | 1250*1250 | ±0.03 | ±0.01 | 10 | YMF-600 | 600 | 4000 | 28 |

| YM1218 | 1800*1250 | ±0.03 | ±0.01 | 10 | YMF-1200 | 1200 | 4500 | 35 |

| YM-2521 | 2500*1250 | ±0.03 | ±0.01 | 10 | YMF-1800 | 1800 | 5000 | 45 |

English

English India

India Canada

Canada Español

Español Français

Français Русский

Русский Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ประเทศไทย

ประเทศไทย Indonesia

Indonesia